Do Shipping Containers Need Ventilation?

2024-11

Vents are crucial in shipping containers, especially if you are looking to build your own container home or use containers to store perishables or expensive equipment.

Without shipping container vents, moisture-sensitive and perishable goods that you store in it can rot away due to lack of proper circulation.

The airtight design of containers can pose a problem for private service due to lack of flow. That’s why a proper ventilation system is vital for a containerized home, storage space, and office.

Passive Ventilation

Passive ventilation allows you to modify your container home or office without any external equipment or systems to maintain ideal temperatures. Placing vents on opposite sides allows air to blow in and out of your containers.

You can also ventilate your storage unit by making design modifications to utilize the wind flow through the unit. Strategically placing the windows on your walls' sides allow better circulation through the unit to remove stale air.

Examples include using ridge vents, creating provision for windows, and installing the container at an appropriate wind location.

Side Vents vs. Roof Vents: Which is Better for Container Ventilation?

Side vents and roof vents serve different purposes, so you need to choose based on your budget and application.

Louver vents or side vents are cheaper and easier to install. Place side vents in a diagonal position (one high and the other low) for cross-ventilation. Side vents also do not interfere much with the design of the unit. If your shipping container requires a large amount of ventilation, install multiple vents.

A turbine or rooftop vent can extract a high volume of stale air. It also disperses moisture faster. Installing a rooftop vent can be complex and requires professional help. Most people use both side and roof vents in containers for effective ventilation.

What Problems Can Poor Ventilation Cause in Containers?

Poor ventilation can severely affect the quality of goods you store and the health of the people living inside. Some common problems that a shipping container can face are:

Mold

Mold is a common issue in damp, moist environments. Lack of airflow can cause the accumulation of moisture and create the ideal conditions for this fungus to grow. Not only is mold difficult and expensive to remove, but its fumes can also have harmful effects on people.

Rust

Steel and other metal parts in your unit can rapidly corrode in the presence of moisture. This can severely affect your plumbing system and other pipelines and lead to high repair costs.

Bad Odors

Poor ventilation can lead to excessive moisture buildup, which can create musty odors in the container. Old rooms with a lack of cross-ventilation typically build up any lingering odor and emit a foul smell.

Diseases

Lack of circulation can lead to pneumonia, dry eyes, and nausea. Poor ventilation is also connected to common respiratory diseases like asthma.

When Do You Need Shipping Container Vents?

If you plan on using the shipping container only for storing items or equipment that are not sensitive to temperature changes, the existing vents may work fine. Remember that a basic container vent only allows a minimal amount of airflow inside. You can store lawnmowers, athletic equipment, and similar items in these conditions.

You might have to modify your outlets and intake vents to use units as storage space for perishable items or chemicals that are susceptible to explosion or fire.

You can make such modifications when you buy shipping containers - rental plans usually allow only minimal changes to the unit.

What Items Require Ventilation for Storage?

- Household items - Use ventilation to protect items that heat or moisture can damage easily during moves, donation drives, or remodels.

- Heavy machinery and vehicles - Use moderate temperatures and good air circulation to avoid repair to machinery and automobiles.

- Dry goods - Condensation can cause dry goods to rot. A well-ventilated unit can keep your good dry and cool.

- Chemicals and pressurized gases - These items must meet temperature and storage regulations. You'll need to check the laws and with your container provider.

How to Determine Vent Quantity for Your Container

Experts use various factors such as weather changes, wind speed, air movement and direction, and average surrounding temperature to identify the cause of condensation.

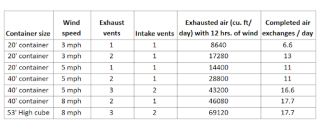

You can start by determining the wind speed and direction and then place your inlet vent and exhaust vent accordingly. A common rule of thumb is that exhaust vents can draw 4 cubic ft. / min /1 mph of wind. One unit is sufficient for slow wind speeds. Higher wind speed requires more vents.

This table gives a general idea of the number of exhaust vents and air exchange rates for different container sizes.

Note: These values will change with the type of vents you are installing.

Coating your containers with light color paints or adding insulation can be a simple yet effective way to maintain optimum temperatures.

Shipping containers that function as homes, offices, and storage units need adequate air circulation to maintain the ideal temperature, airflow, and humidity. Ensure the right number and types of container vents to prevent damage to your stuff. Seeking expert advice can help you make an informed decision.

How can we help?

At HUAXIA VENTILATION, we focus on creating solutions that suit versatile needs. Our team of dedicated delivery and engineer specialists pays keen attention to your requirements and ensures that you get containers for rent and sale at competitive prices with unparalleled service.

Our shipping container offices have IP53-65 weather louver with dust filter, insect net, fan blower and other on-demand accessories for your convenience.

Previous page

Related News